Addition Agent

ひさご「生型用添加剤 WA-1、JHモイスチャー、JHオイル」をご紹介します。

-Ingredients and properties-

| JH Oil | WA-1 | JH Moisture | |

| Application | Carbonaceous filler | Wetting agent | Surface stabilizer |

| Properties | ・Carbon supply source ・Casting surface superior to carbon powder ・Particles contained by liquid ・No sulfur or ash ・Reduced CO2(carbon neutral) ・Good sand fluidity for improved packing density | ・Draws out the vitality of bentonite (improves swelling and plasticity threshold). ・Better surface consistency through microadditive volumes. ・Lower moisture with same CB possible. ・Reduces “sand inclusion” defects. | ・Properties include transparency, low viscosity, neutral pH, odorlessness, and non-toxicity. ・Adds moisture to the mold surface (vitalizes bentonite). ・Prevents the sand from drying at high temperatures, avoiding sand inclusions and erosion. |

| Ingredients | Vegetable oil-based, liquid | Polyacrylic acid soda, powder | Polyacrylic acid soda, aqueous solution |

| Usage method | 0.01-0.03% added to sand 100-300 g per 1 t of sand | 0.005-0.008% added to sand 50-80 g per 1 t of sand | Sprinkled on surface after casting |

| Examples of efficacy | ||||||||||||||||||||||||||||||||

| JH Oil | WA-1 | JH Moisture | ||||||||||||||||||||||||||||||

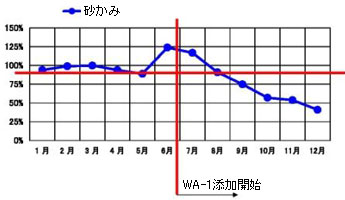

Example of improvement in mold properties with JH oil | Examples of the efficacy of WA-1 at companies that adopted it

※Company B is an example of fewer sand inclusion defects in FCD parts. ※See Figure 1 below. | Examples of the efficacy of JH Moisture

※Graph of changes in surface consistency during high-temperature drying with JH Moisture ※See Figure 2 below. |

||||||||||||||||||||||||||||||

| Examples of efficacy | |

WA-1 ※Figure 1 ※Fewer sand inclusion defects in FCD parts at Company B  | JH Moisture ※Figure 2 ※ Graph of changes in surface consistency during high-temperature drying with JH Moisture  |